Stress Analysis

Beyond simple business support, we provide engineering services to further check the integrity of the joints applied to the site using the stress analysis program.

Stress Analysis Characteristics

- Changing the piping route and calculating back data after stress analysis

- CAESAR ii Simulation

- -ISO Drawing Verification and INPUT DATA Creation

- -Stress Analysis Report Output and Proposal for Application after Reviewing Stability and Economic Efficiency

- Selection of whether or not to apply the expansion joint and its location

- Review of stability according to selection of qtiranca and Guide

- Reviewing the safety rate range due to expansion of piping

- Changing the piping route and calculating back data after stress analysis

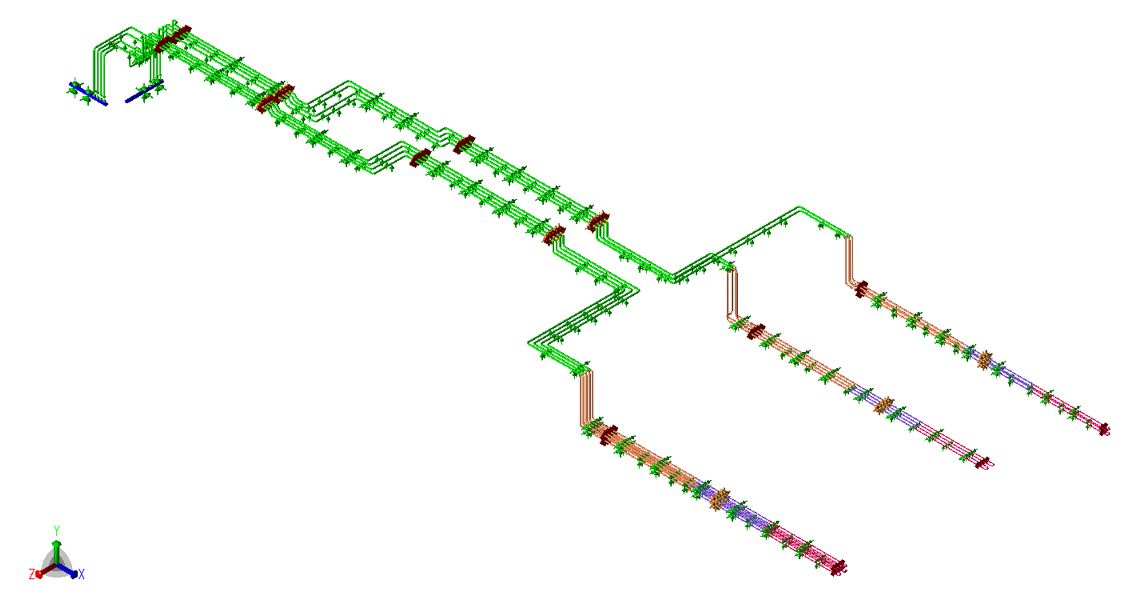

PROGRAM : CAESAR II

Industry-standard piping stress analysis program, which supports a wide range of CODEs and is the world's most popular (Piping Stress Analysis)

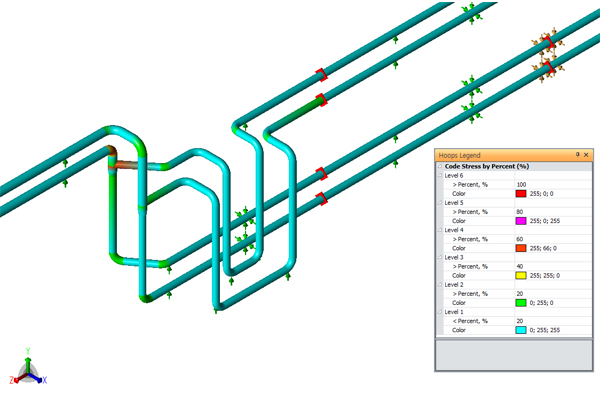

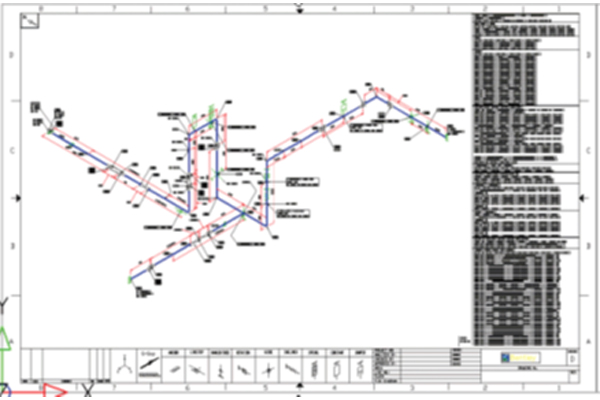

ISOVIEW-1

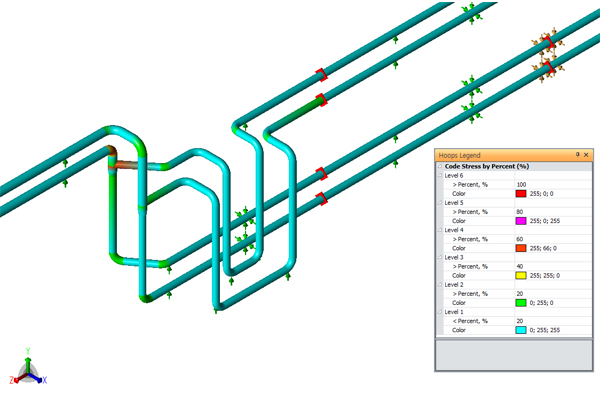

CODE STRESS(%) VIEW

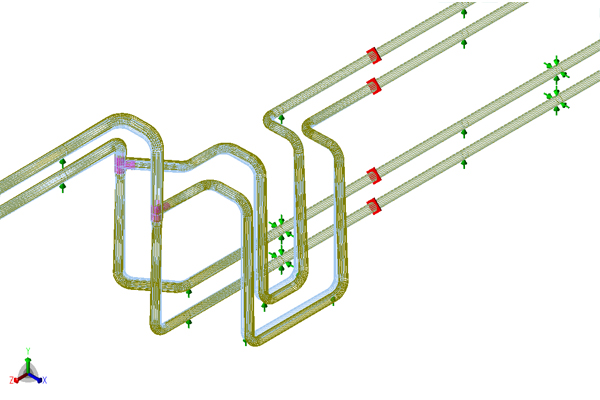

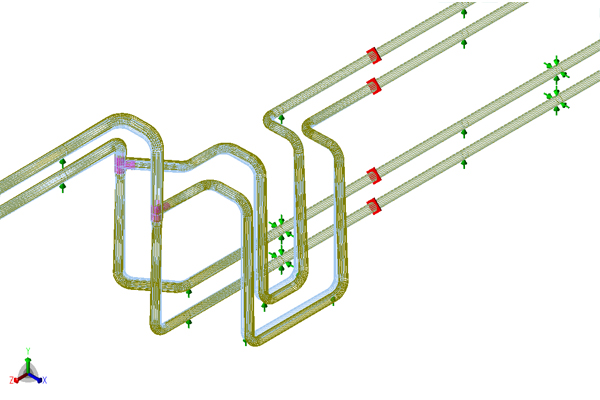

DISPLACEMENT VIEW

CODE STRESS(%) VIEW

DISPLACEMENT VIEW

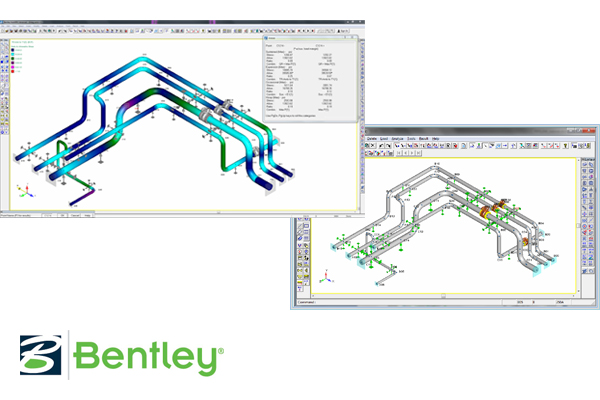

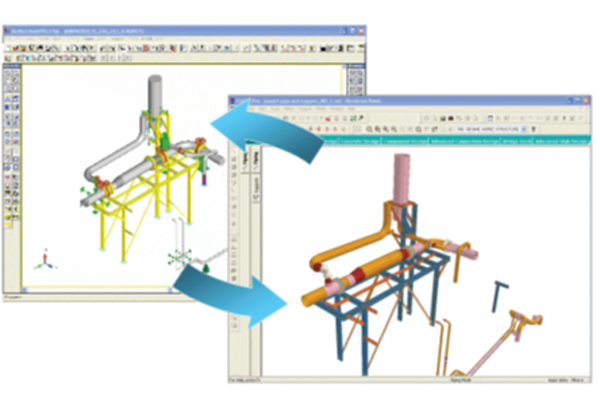

PROGRAM : AUTO PIPE

Advanced Design and Analysis Program to Calculate Pipe Code Woong, Loads and Deformation under Static and Dynamic Load Conditions

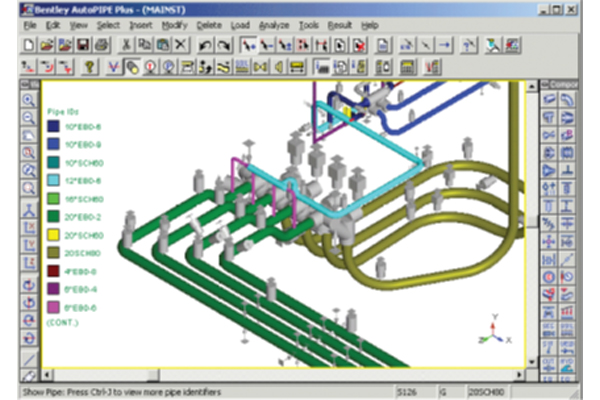

AutoPiPE

- Advanced Design and Analysis Program to Calculate Pipe Code Woong, Loads and Deformation under Static and Dynamic Load Conditions

- Exclusive object-based graphical user interface

- Advanced analysis functions for various piping environments

- Review the results of the analysis

- Interaction with ProjectWise, CAE, STAAD.Pro, and Plant CAD systems

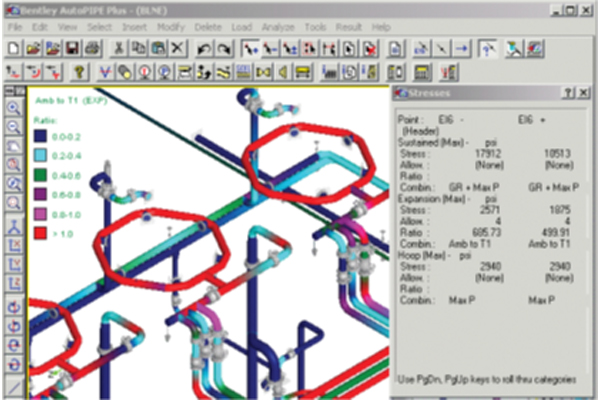

Quickly identify and identify critical areas through color display areas

Automatic generation of stress ISO drawings with full dimensions

bidirectional integration with STAAD pro V8i, a structural analysis program

Rapid stress verification through graphic models